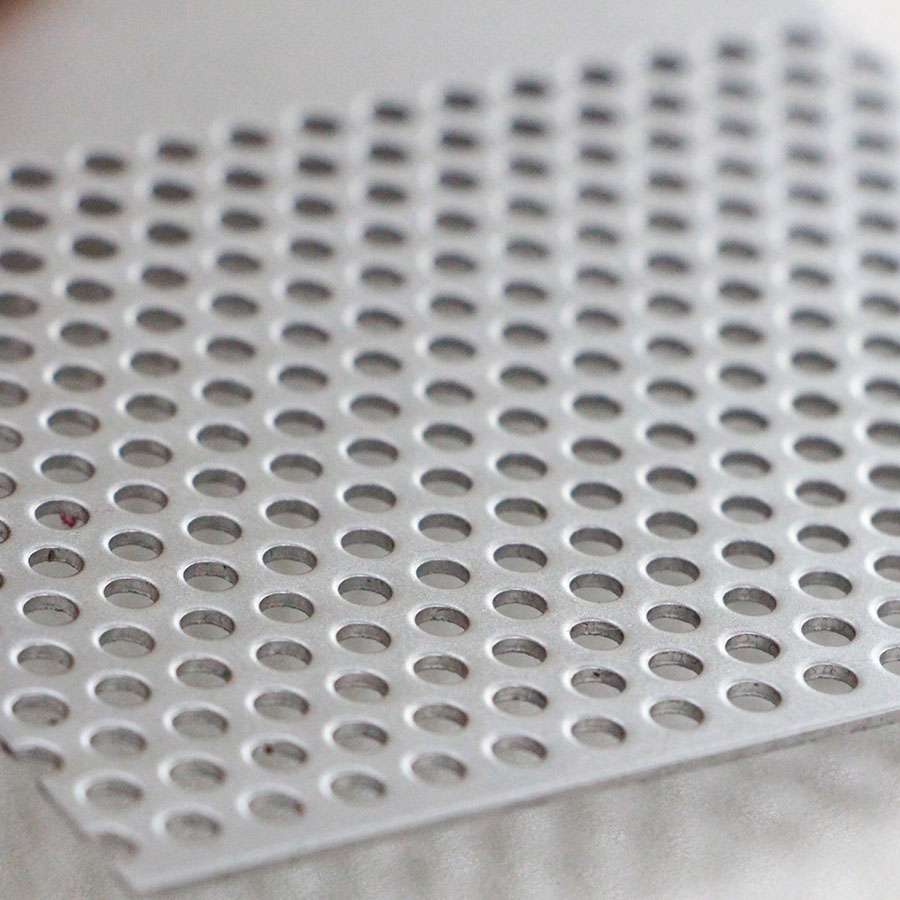

Round hole perforated metal sheet is one of the most classic and widely used types of perforated metal. Manufactured using advanced CNC punching technology, this product features evenly spaced circular holes across a sheet of metal. As the most common perforation pattern, round holes provide a balanced combination of performance, aesthetics, and cost-effectiveness, making them an industry favorite for architectural, industrial, and functional applications.

Core Features and Parameters

Round hole perforated metal sheet offers broad flexibility through customizable specifications. Materials can include mild steel, stainless steel (304/316), aluminum, galvanized steel, and even copper. This allows engineers and designers to choose the right balance between strength, corrosion resistance, and appearance.

Thickness ranges from 0.5mm to 12mm, suitable for everything from fine filtration to heavy-duty structures. Hole diameters can be as small as 0.8mm for precision applications or larger than 200mm for decorative or ventilation use. Porosity varies between 3% and 80%, giving designers full control over airflow, light transmission, and structural performance.

Arrangement styles include straight patterns or staggered patterns (such as 60° plum blossom). The staggered layout enhances permeability and ensures a more uniform stress distribution across the sheet. Surface treatments like painting, powder coating, anodizing, electroplating, or hot-dip galvanizing further improve corrosion resistance and allow for diverse design finishes.

Core Advantages and Potential Considerations

Round hole perforated sheets have several key advantages:

-

Functionality and versatility – The sheet’s performance can be precisely tailored by adjusting thickness, hole size, and spacing, allowing it to meet hundreds of different application requirements.

-

Cost-effectiveness – Round hole molds are simple to manufacture, and punching production is highly efficient, making these sheets one of the most economical perforation solutions for large-scale projects.

-

Aesthetic value – The clean and geometric round hole pattern delivers a modern, industrial look. Combined with various materials and finishes, the panels adapt to many architectural styles.

-

Strength and durability – With uniform stress distribution around the holes, the sheet offers excellent load-bearing capacity while resisting cracking, fire, moisture, and UV exposure.

-

Ease of processing – These sheets can be cut, bent, welded, or crimped using standard tools, simplifying installation.

Potential considerations include burrs created during punching, which may require deburring for smoothness; additional weight compared to plastic or wood; and limited design uniqueness compared to more complex patterns like hexagonal or decorative perforations.

Key Applications of Round Hole Perforated Metal Sheet

1. Architectural Decoration and Facade Systems

Round hole sheets are widely used in facades, ceilings, partitions, railings, and screens. They create striking light and shadow effects as natural light changes, enhancing the building’s modern and dynamic appearance.

-

Compared with alternatives:

-

Solid metal panels block all light and appear bulky.

-

Wooden grilles are prone to deformation, cracking, and flammability.

-

Woven metal mesh is costly and lacks precise aperture control.

-

Conclusion: For modern architecture requiring durability, aesthetics, and balanced functionality, Round Hole Perforated Metal Panels are the superior choice.

2. Industrial Screening and Filtration

In mining, coal, grain, and chemical industries, these sheets are used in vibrating screens, filter screens, and filter element holders. The consistent apertures provide accuracy, while the metal substrate ensures strength, heat resistance, and long service life.

-

Compared with alternatives:

-

Woven mesh deforms easily and wears out quickly.

-

Polyurethane screens fail under high heat and tear easily.

-

Plastic perforated sheets are brittle and unsuitable for heavy-duty use.

-

Conclusion: For demanding screening applications, round hole perforated sheets outperform woven mesh, polyurethane, and plastic alternatives.

3. Mechanical Equipment Protection and Safety Facilities

Used for machine guards, ventilation covers, ladder steps, and guardrails, these sheets protect workers while allowing ventilation and cooling. The circular holes also provide anti-slip performance when used as steps.

-

Compared with alternatives:

-

Welded wire mesh may suffer from broken welds.

-

Expanded metal mesh lacks flatness and aperture precision.

-

Plexiglass covers are brittle and flammable.

-

Conclusion: For industrial environments requiring both safety and durability, round hole perforated sheet is the best option.

4. Electronic Product Enclosures and Audio Equipment

Applications include speaker grilles, server cabinet doors, and appliance ventilation panels. These sheets offer EMI/RFI shielding, airflow, and durability while maintaining an attractive design.

-

Compared with alternatives:

-

Plastic mesh lacks shielding and durability.

-

Ordinary perforated iron rusts easily.

-

Aluminum sheets are lighter but prone to dents.

-

Conclusion: For electronic enclosures and audio equipment, stainless steel or galvanized round hole perforated panels provide superior performance.

Summary and Recommendations

Round hole perforated metal sheet may not be the most striking pattern, but it is the most reliable, versatile, and cost-effective. With balanced functionality, strength, and aesthetics, it has become a cornerstone material in architecture, industry, and equipment protection.

HIGHTOP offers Round Hole Perforated Metal Panels with unparalleled customization in materials, hole sizes, thicknesses, and finishes. Our CNC equipment ensures precision and uniformity, while our engineering team provides expert consultation to meet project-specific requirements. Combined with strict quality assurance, HIGHTOP guarantees reliable, high-performance products.

Choosing HIGHTOP means selecting a trusted partner to enhance your projects with durable, stylish, and functional round hole perforated sheeting.

Request a Quote

Please email us via the contact form below, we will get back to you as soon as possible.