Choosing fence materials today goes beyond simply marking boundaries. Fences must deliver safety, durability, aesthetics, privacy, ventilation, and low lifecycle cost. HIGHTOP Metal Mesh recommends choosing the best material and process to match the project environment, function, and budget rather than seeking a single “best” product.

Comparison of Common Metal Fence Materials

| Material Type | Core Advantages | Limitations | Best Application Scenarios |

|---|---|---|---|

| Stainless Steel | Excellent corrosion resistance, high strength, premium look, low maintenance | Higher initial cost | Coastal facades, landmark projects, high-security sites |

| Carbon Steel / Welded Wire Mesh | Strong, economical, widely available | Needs protective coatings; rust risk if coating fails | Construction sites, warehouses, temporary fencing |

| Aluminum Alloy | Lightweight, corrosion-resistant, easy to fabricate | Lower absolute strength vs. steel; higher cost than basic mesh | Balconies, landscape fences, decorative enclosures |

| Zinc-Steel (Modular Systems) | Cost-effective, durable, fast installation | Design homogenization, limited customization | Residential communities, municipal barriers |

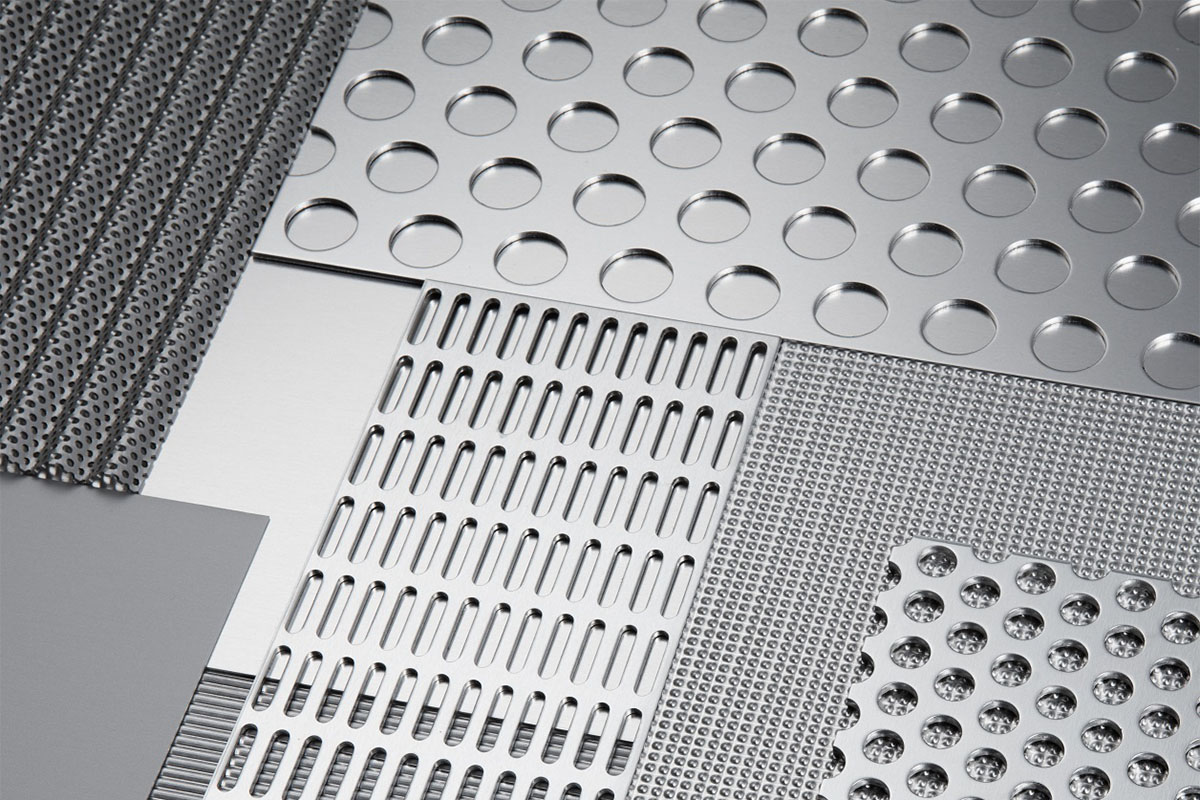

| Perforated Metal Panels | Custom patterns, privacy + ventilation, architectural finish, long life | Higher upfront cost vs. basic welded mesh | Commercial façades, privacy screens, high-end residential fences |

How to Choose the Right Metal Fence

-

Assess the Environment

-

Coastal or industrial zones → prioritize corrosion resistance (304/316 stainless steel).

-

Standard urban environment → hot-dip galvanized or powder-coated steel often suffices.

-

-

Define Functional Needs

-

Need ventilation or visual permeability? Consider expanded metal or perforated panels.

-

Require maximum security? Choose heavy-gauge welded mesh or stainless steel panels.

-

-

Evaluate Aesthetics & Brand Expression

-

Want a unique building skin? Perforated panels allow logos, gradients, and custom artwork.

-

Need a classic look? Stainless steel or powder-coated profiles fit well.

-

-

Total Life-Cycle Cost

-

Compare initial cost with long-term maintenance. Stainless steel may cost more upfront but reduces lifecycle costs.

-

Why HIGHTOP Perforated & Expanded Metal Solutions

HIGHTOP Metal Mesh specializes in metal fence systems that combine performance with design:

-

Customization: CNC perforation, laser-cut patterns, and expanded/pressed meshes to match architectural intent.

-

Surface Systems: PVDF/fluorocarbon coatings, anodizing, powder coating, and wood-grain finishes for durability and aesthetics.

-

Engineering Support: Wind-load and structural advice, prefab modular systems, and concealed fixing solutions for clean installation.

-

Quality & Supply: Full production chain and strict QC to deliver consistent panels at competitive lead times.

Use cases where HIGHTOP excels:

-

Commercial façades with sun-shading and branded patterns.

-

High-end residential gates and privacy screens.

-

Industrial enclosures needing ventilation and visual screening.

-

Public infrastructure requiring low maintenance and long life.

Installation & Maintenance Tips

-

Edge Protection: For expanded or cut meshes, treat cut edges (paint or galvanize) to avoid corrosion starts.

-

Fixing & Support: Use appropriate support frames and allow for thermal expansion on long runs.

-

Cleaning: Occasional rinsing or soft-pressure wash; avoid abrasive cleaners on coated finishes.

-

Inspection: Annual quick checks for coating damage and fastener integrity to extend service life.

FAQ

Q1: Which metal fence lasts the longest outdoors?

A: In most outdoor conditions, 316 stainless steel offers the best long-term corrosion resistance. For standard urban settings, hot-dip galvanized steel with proper coating also performs well.

Q2: Are perforated metal panels secure?

A: Yes — when specified with proper thickness, support framing, and fixing details, perforated panels provide strong, secure barriers while adding privacy and design value.

Q3: Can I print a logo or image into a fence?

A: Absolutely. CNC laser-cut or perforated panels can reproduce logos, text, and pixel gradients to become a branded architectural element.

Q4: Do perforated or expanded panels reduce maintenance cost?

A: They can. Durable base materials plus high-quality coatings (PVDF) minimize repainting and maintenance, reducing lifecycle costs compared with lower-quality painted steel.

Q5: How does HIGHTOP help with design and engineering?

A: HIGHTOP offers pattern libraries, structural design guidance, wind-load calculations, and prefabricated modular systems to speed installation and ensure performance.

Request a Quote

Please email us via the contact form below, we will get back to you as soon as possible.