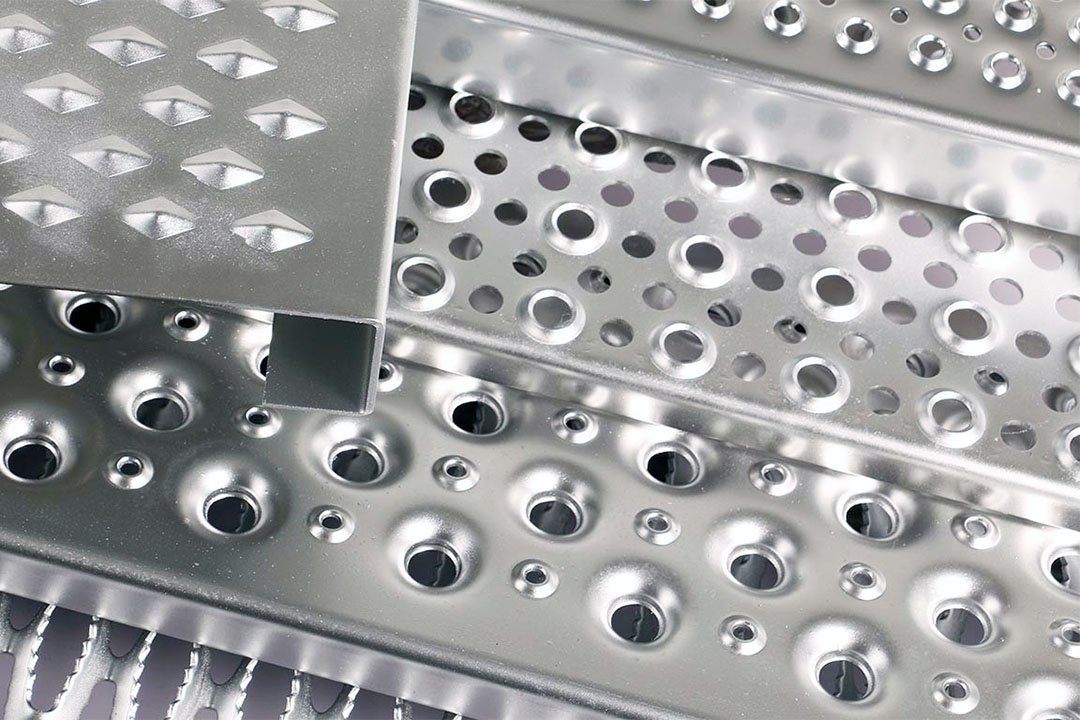

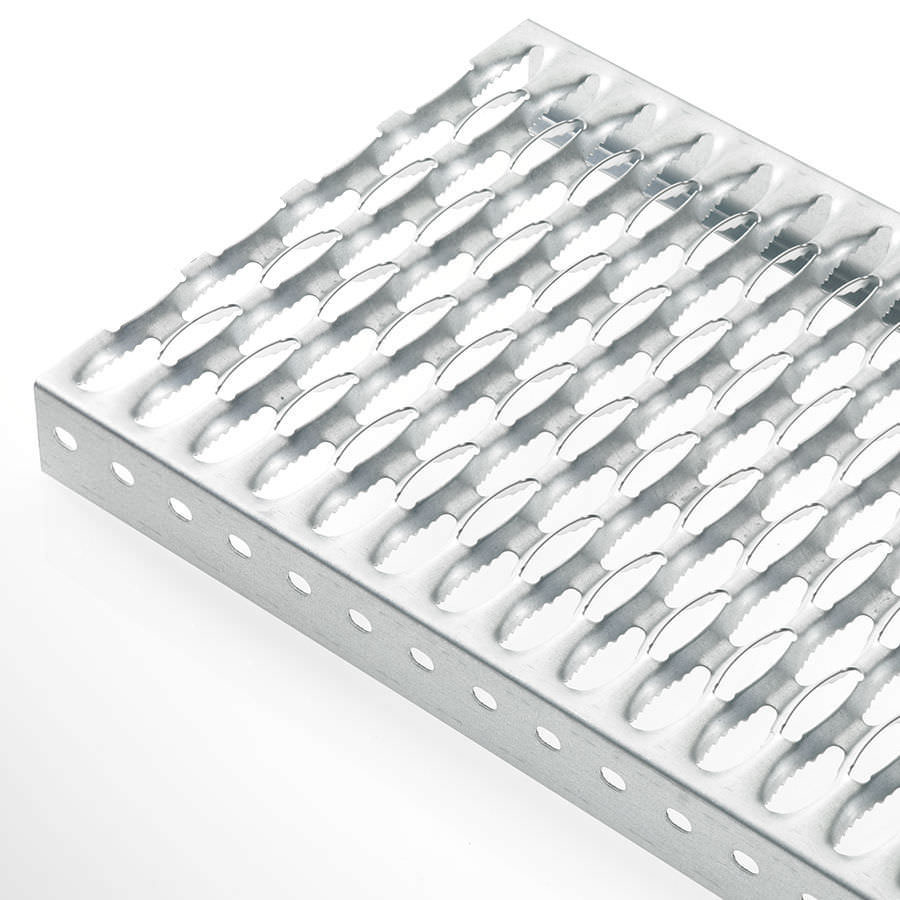

Perforated metal anti-slip pedals are widely used in industrial platforms, transportation facilities, and construction sites where safety, durability, and load-bearing capacity are critical. These pedals feature unique hole designs—such as star-shaped, crocodile-mouth, or fish-eye patterns—combined with raised surfaces to provide superior slip resistance, even in oily, icy, or wet environments. While they offer a number of significant benefits, there are also some limitations that must be considered when selecting the right solution for a specific application.

Advantages of Perforated Metal Anti-Slip Pedals

1. Excellent Anti-Slip Performance

The raised surface designs (0.5–2 mm in height) create multiple points of contact with footwear. A single foot typically engages 3–4 raised points, improving anti-slip efficiency by over 40% compared to flat surfaces. This ensures stability in environments such as offshore platforms, rainy ship decks, or icy truck steps.

2. High Strength and Durability

These pedals are available in Q235 steel, stainless steel, or aluminum alloy with thicknesses ranging from 1.5 mm to 5 mm. Depending on the material, they can support loads of 3–5 tons per square meter. For long-term corrosion resistance, hot-dip galvanizing can be applied, extending the service life to over 20 years—even in marine or chemical environments.

3. Efficient Drainage and Cleaning

With an open area of 10%–30%, perforated metal anti-slip pedals allow rapid drainage of water or other liquids. This is particularly advantageous in sewage treatment plants, where cleaning efficiency can be improved by as much as 60%.

4. Lightweight and Easy Installation

Weighing only 40% of a solid steel plate of the same size, these pedals are easier to handle and install. They also allow for bending and shearing, providing flexibility in custom designs.

Limitations of Perforated Metal Anti-Slip Pedals

Despite their benefits, there are a few considerations:

- Fabric Snagging – The raised points on the surface can catch or tear soft fabrics, which might be an issue in certain work environments.

- Higher Initial Cost – Compared to standard steel plates, the initial investment is typically about 20% higher due to material and processing requirements.

While these drawbacks are relatively minor in heavy-duty industrial applications, they may influence budget decisions or material selection for less demanding uses.

Application Scenarios and Performance Comparisons

1. Industrial Platforms (Chemical Plants, Power Plants, Offshore Facilities)

- Challenge: Corrosion and slip hazards.

- Solution: 316 stainless steel with star-shaped holes for an anti-slip coefficient greater than 0.6.

- Benefit: Up to three times the lifespan of fiberglass alternatives in severe corrosion environments.

2. Transportation Facilities (Trucks, Trains, Ships)

- Challenge: Slippage during rain or snow and frequent deformation from heavy use.

- Solution: 2–3 mm aluminum alloy with alligator-mouth holes, reducing weight by 30% while meeting EN ISO 14122 standards.

- Benefit: Lifetime maintenance-free operation; ideal for ports and outdoor staircases.

3. Construction Steel Gangplanks

- Challenge: Slippery bamboo boards and low load capacity.

- Solution: 4 mm hot-dip galvanized steel with eyelets, exceeding GB 25849 standards.

- Benefit: Load capacity far greater than bamboo or ordinary steel grating, with a 10-year service life for double-layer paving.

Competitive Product Comparison

| Product Type | Slip Resistance | Load Capacity | Corrosion Resistance | Lifespan | Cost |

|---|---|---|---|---|---|

| Perforated Metal Anti-Slip Pedals | Best | Best | Excellent | 15–20 years | Medium-High |

| Patterned Steel Sheet | Poor | Good | Poor | 5–8 years | Low |

| Fiberglass Stepping Board | Medium | Poor | Best | 8–10 years | Medium |

| Rubber Anti-Slip Mat | Excellent | Poor | Medium | 2–3 years | Low |

| Composite Pedals | Excellent | Medium | Optimal | 20+ years | Very High |

Selection Recommendations

- Chemical/Offshore Platforms: 316 stainless steel, star-shaped holes, thickness ≥ 3 mm.

- Rail Transit: 5052 aluminum alloy, alligator-mouth holes, thickness 2.5 mm.

- Construction Sites: Hot-dip galvanized steel, eyelet holes, thickness 4 mm.

Perforated metal anti-slip pedals combine outstanding slip resistance, load capacity, and corrosion protection in a lightweight, easy-to-install design. Their raised surface patterns provide unmatched safety in challenging environments, while their high-strength materials ensure years of reliable service. Although the initial investment is higher than for some alternatives, the extended lifespan, maintenance-free operation, and safety improvements often make them the most cost-effective choice in the long run.

From offshore platforms to urban rail systems and high-rise construction sites, these pedals deliver dependable performance where it matters most. By understanding both their advantages and limitations, decision-makers can select the ideal configuration to match their operational and budgetary needs.

Request a Quote

Please email us via the contact form below, we will get back to you as soon as possible.