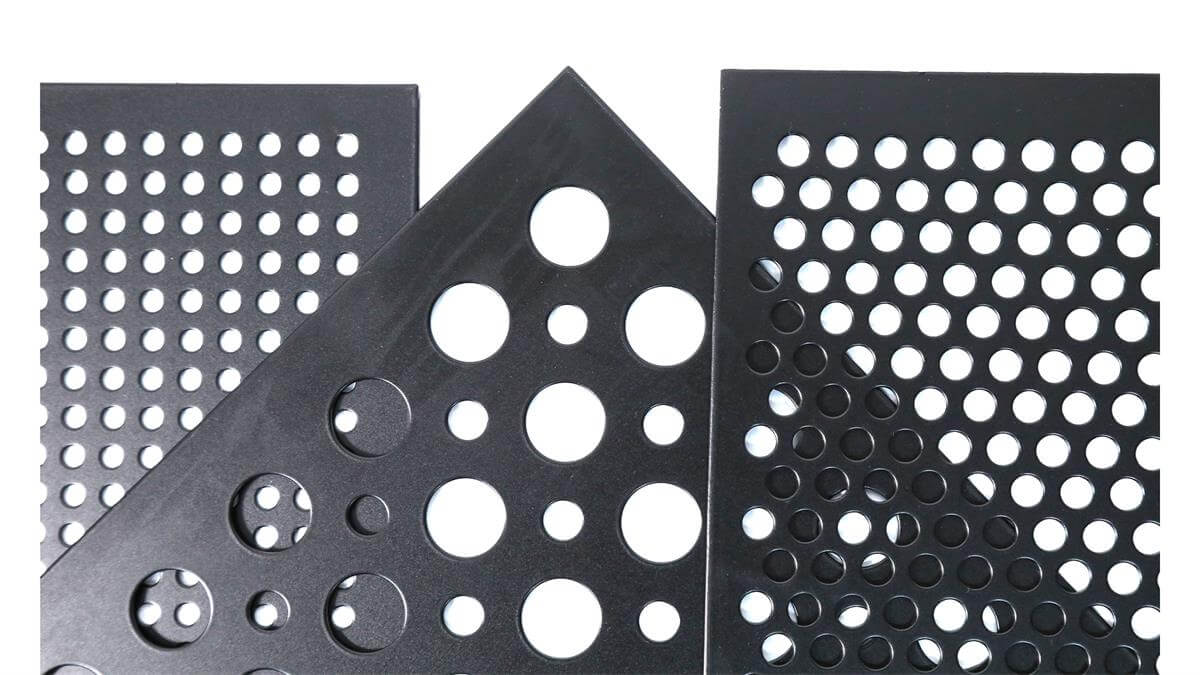

When planning architectural, industrial, or decorative projects, understanding the perforated sheet price is essential for cost control and material selection. A perforated sheet is a metal sheet processed through CNC punching, stamping, and cutting to create various hole patterns. As a professional manufacturer in China, HIGHTOP Metal Mesh produces perforated sheets using stainless steel, low-carbon steel, galvanized steel, aluminum, and copper. Our advanced punching equipment supports circular, square, diamond, and customized pattern holes to meet diverse project requirements.

What Makes Perforated Sheets Popular?

Perforated sheets offer a balance of functionality, aesthetics, and cost efficiency, making them widely used in architecture, industrial filtration, acoustic systems, HVAC protection, and furniture design.

Key Benefits

-

Customizable patterns: Round, square, hexagonal, fish scale, plum blossom, and decorative laser-cut designs.

-

Breathability & light transmission: Ideal for facades, acoustic panels, and ventilation systems.

-

Lightweight: Especially aluminum perforated sheets, reducing engineering load and transportation cost.

-

Environmental performance: Perforated designs help improve natural lighting and reduce HVAC energy consumption.

-

Sound absorption: Frequently used in auditoriums, theaters, and mechanical equipment enclosures.

Factors That Influence Perforated Sheet Price

The perforated sheet price depends on multiple cost variables. Understanding these components helps designers and procurement teams make smarter decisions.

1. Material Cost

Different materials vary significantly in price and performance:

| Material | Features | Cost Impact |

|---|---|---|

| Stainless Steel | High corrosion resistance | Higher |

| Aluminum | Lightweight & anti-rust | Medium |

| Galvanized Steel | Budget-friendly, rust-resistant surface | Lower |

| Copper | Decorative, conductive | High |

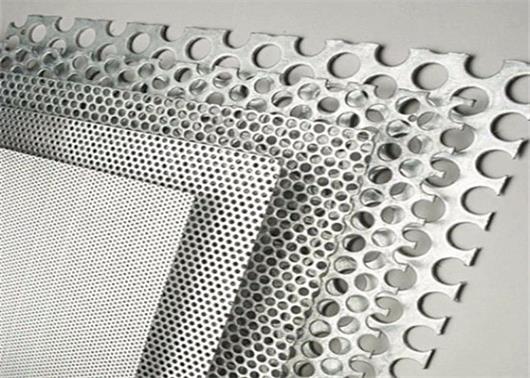

The sheet thickness and size (e.g., 1m×2m, 1.2m×2.4m, or customized formats) also affect final cost.

2. Processing Cost

Processing complexity has a major impact on the perforated sheet price.

| Factor | Effect on Cost |

|---|---|

| Number of holes | More holes = longer machine runtime |

| Hole size & spacing | Precision increases cost |

| Pattern complexity | Custom and artistic patterns increase cost |

| Width & length | Oversized panels require special machinery |

Additional processing steps such as bending, rolling, cutting, welding, painting, anodizing, or coating will further affect pricing.

3. Additional Expenses

-

Custom mold fees for non-standard hole designs

-

Packaging and logistics costs (varies by region and size)

-

Installation labor, especially for architectural façade projects

Comparing Perforated Sheets with Other Materials

| Application Scenario | Perforated Sheet | Alternative Material | Comparison Result |

|---|---|---|---|

| Exterior Walls | Ventilated, reduces heat load | Solid aluminum sheet | Perforated sheet is more energy-efficient |

| Screening & Filtration | High accuracy, long lifespan | Woven mesh | Perforated sheet is more durable |

| Interior Partition | Light-filtering, modern style | Drywall | Perforated sheet provides transparency & flexibility |

Perforated sheets often offer better performance, especially when ventilation, aesthetics, and long-term durability are required.

Why Choose HIGHTOP Metal Mesh?

As a leading perforated sheet manufacturer in China, HIGHTOP Metal Mesh provides:

-

Full industrial chain advantages for competitive pricing

-

Advanced CNC punching machines supporting high accuracy and large-format panels

-

Strong customization capability for architectural and industrial design projects

-

Complete quality inspection and post-processing services

-

Engineering support, including material selection, cost optimization, and installation guidance

We supply perforated sheets worldwide to architects, contractors, filtration companies, and industrial manufacturers.

Request Your Project Estimate

Understanding the real perforated sheet price requires analyzing materials, hole patterns, specifications, and post-processing needs. At HIGHTOP Metal Mesh, we offer free consultation and quotation services to help you optimize performance and budget.

Final Summary

Perforated sheets are versatile materials widely used in modern architecture and industry. Their cost varies based on material type, punching complexity, customization, and post-processing requirements. For accurate pricing and optimized product selection, partnering with an experienced manufacturer like HIGHTOP Metal Mesh ensures both quality and value.

Request a Quote

Please email us via the contact form below, we will get back to you as soon as possible.