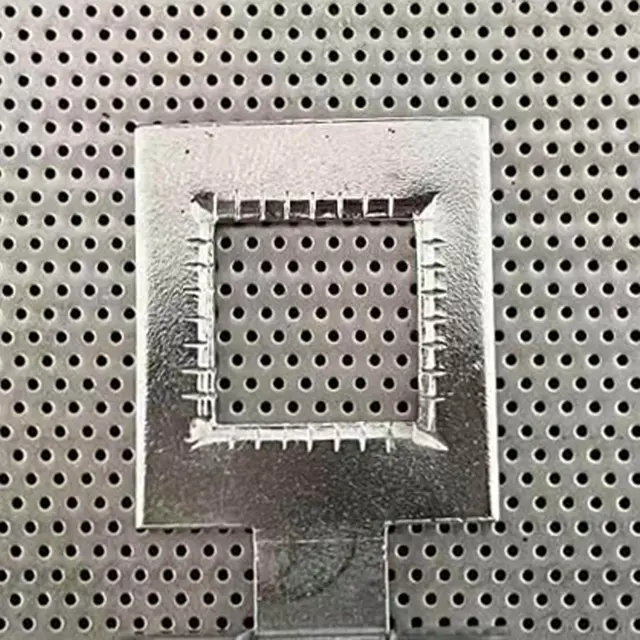

Micropores Perforated Metal Panels are a new generation of functional materials designed for precision, durability, and versatility across a wide range of industries. Produced using advanced technologies such as laser drilling, these panels are made from stainless steel, aluminum alloy, or mild steel sheets with pore diameters ranging from 0.1 mm to 1.0 mm. Their exceptional accuracy, strength, and aesthetic qualities make them superior to traditional perforated or woven mesh solutions.

Key Features of Micropores Perforated Metal Panels

The performance of these panels depends on several technical parameters:

-

Pore Diameter: 0.1 mm – 1.0 mm, directly influencing filtration accuracy, acoustic performance, and air permeability.

-

Plate Material: Options include stainless steel (304/316), aluminum alloy, and mild steel. Stainless steel, especially grade 316, provides excellent resistance to chlorides and harsh chemicals.

-

Thickness: 0.2 mm – 2.0 mm, which must correspond to pore size to ensure mechanical strength.

-

Arrangement: Flat or 60° staggered (plum blossom), with staggered layouts offering better uniformity and structural stability.

-

Porosity Ratio: 1% – 30% or higher, impacting both filtration capacity and acoustic performance.

These features enable Micropores Perforated Metal Panels to combine functional precision with long-term durability.

Advantages and Challenges

Advantages:

-

Precision Control: Provides uniform pore sizes for high-accuracy filtration, screening, and sound absorption.

-

Durability: Metal construction ensures resistance to impact, high temperatures, and corrosion.

-

Hygienic and Aesthetic: Smooth surfaces and uniform holes are easy to clean, making them suitable for food and medical applications.

-

Weather Resistance: Fireproof, moisture-proof, and UV-resistant, ensuring long service life and recyclability.

Challenges:

-

High Manufacturing Cost: Laser drilling requires advanced equipment and increases production expenses.

-

Clogging Risk: Micropores can become blocked during dust-heavy operations.

-

Design Complexity: Requires precise engineering based on fluid dynamics or acoustic models.

Application Paths of Micropores Perforated Metal Panels

1. High-Precision Filtration and Separation

Used in chemical catalyst recovery, food industry powder screening, and precision sieving systems. These panels outperform woven mesh and polymer membranes due to their superior accuracy, mechanical strength, and long life.

2. Architectural Acoustics and Noise Reduction

In large public spaces such as concert halls, airports, or subway stations, microperforated panels act as effective noise absorbers without the need for porous fillers. They achieve NRC values of 0.8 or higher while maintaining aesthetics, fire resistance, and environmental safety.

3. Electronic Products and Heat Dissipation

Applied in server cabinets, audio grilles, and instrument housings, these panels combine ventilation, dust protection, and electromagnetic shielding. Unlike plastic or woven mesh, they resist static buildup, deformation, and high temperatures.

4. Environmental and Industrial Equipment

In noise barriers, sewage aeration systems, and industrial drying equipment, the panels withstand harsh environments while providing acoustic and ventilation functions. Their longevity and precision outperform fiberglass gratings or ordinary perforated sheets.

Comparison with Other Materials

| Features | HIGHTOP Micropores Perforated Metal Panels | Woven Mesh | Plastic/Polymer Filter Plate | Traditional Sound Absorbing Material |

|---|---|---|---|---|

| Filtration Precision | Extremely high and stable | Average, prone to deformation | High but weak strength | Not applicable |

| Durability | Excellent, heat & corrosion resistant | Low, prone to breakage | Poor, weak against chemicals | Average, moisture damage |

| Sound Absorption (Unfilled) | Excellent, full-range | Poor | Average | Good, but requires porous fillers |

| Environmental Performance | Fireproof, eco-friendly | Average, ages quickly | Questionable | Possible fiber shedding |

| Maintenance | Easy to clean | Difficult | Frequent replacement | High maintenance |

| Lifecycle Cost | Low (long lifespan) | High | High | Medium |

This comparison highlights the long-term value of Micropores Perforated Metal Panels in precision and durability.

Why Choose HIGHTOP?

HIGHTOP specializes in advanced laser drilling manufacturing, offering:

-

High Precision: Smooth hole walls, no thermal deformation, and stable tolerances.

-

Full Customization: Options for material, thickness, pore size, arrangement, and surface treatment.

-

Technical Support: Expert consultation for filtration, acoustics, and fluid dynamics applications.

-

Quality Assurance: Strict quality control from raw material to final inspection.

Micropores Perforated Metal Panels are more than just functional materials—they represent a balance of technology, durability, and design. Their ability to deliver precision filtration, advanced acoustic control, reliable heat dissipation, and environmental resilience makes them indispensable in industries from architecture to electronics. By choosing HIGHTOP, you ensure not only superior material quality but also expert technical support and long-term performance.

For projects demanding high precision and long-lasting reliability, Micropores Perforated Metal Panels are the best solution.

Request a Quote

Please email us via the contact form below, we will get back to you as soon as possible.