What makes a filter material truly reliable in industrial environments? Can it withstand pressure, corrosion, and time? Should you prioritize strength or flexibility? With so many options available, choosing between stainless steel perforated plate and polyester woven mesh can be a challenge.

In industrial filtration, stainless steel perforated plate stands out for strength and durability, while polyester woven mesh offers flexibility and cost-efficiency. Choosing the right material depends on your specific application needs and environmental conditions.

Both materials have proven effective in various industries—from construction and wastewater treatment to textile manufacturing and medical environments. But how do they really compare when it comes to performance, longevity, and cost?

Let’s break it down.

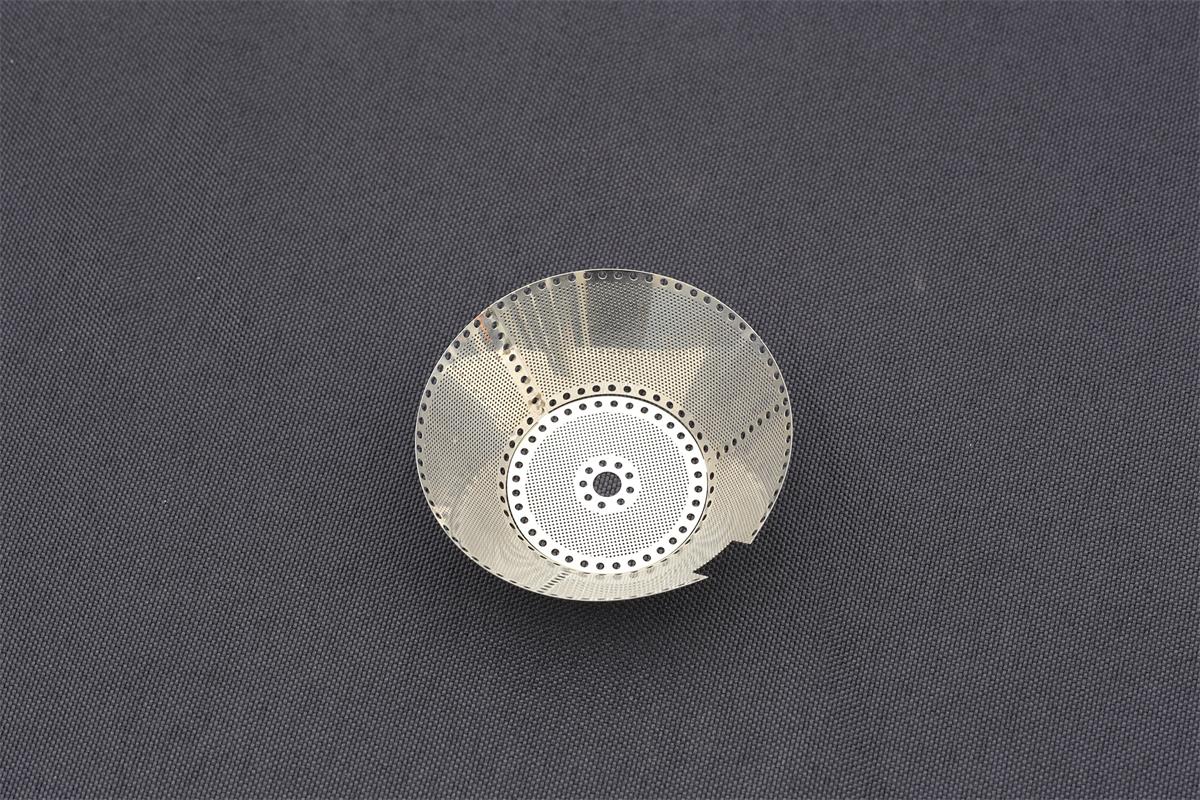

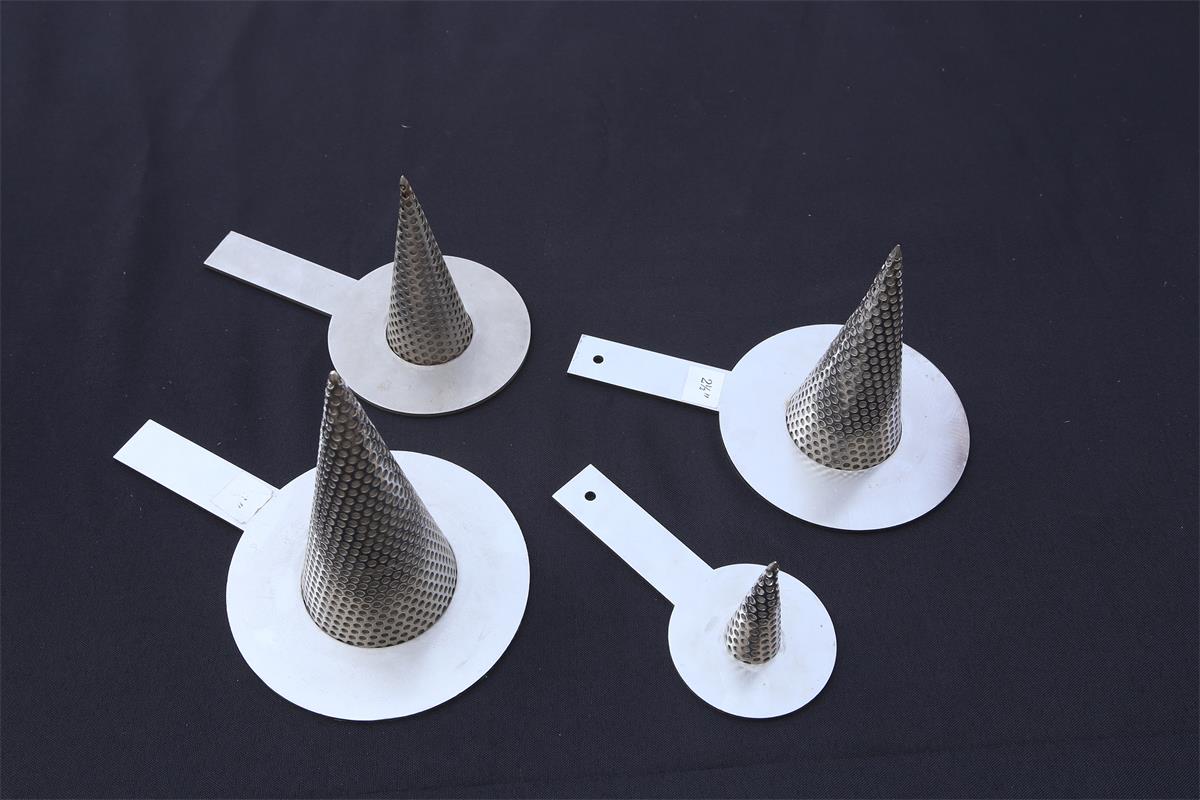

What Is Stainless Steel Perforated Plate?

Stainless steel perforated plate is a solid sheet of stainless steel that has been mechanically punched with a pattern of holes. These holes can be round, square, slotted, or custom-designed to suit specific filtration or structural needs.

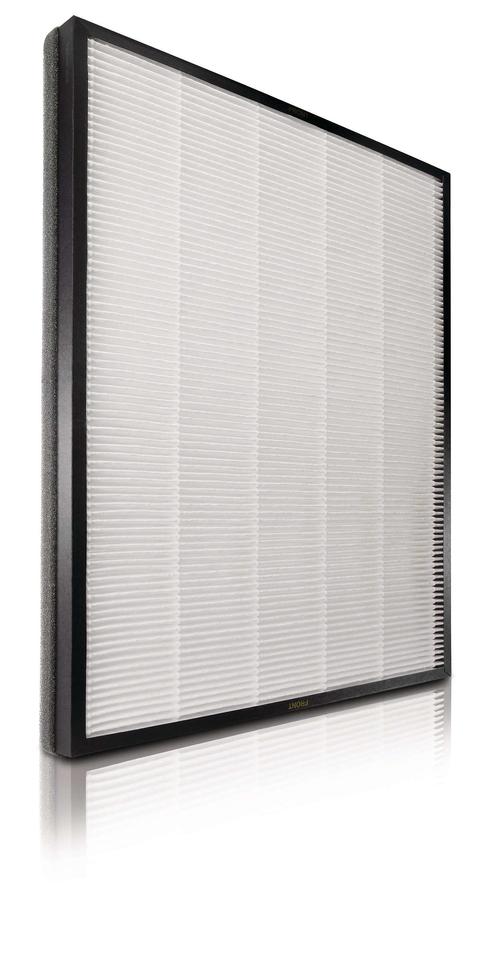

Because it’s made from stainless steel, it offers high resistance to rust, corrosion, and physical damage. It’s commonly used in heavy-duty industrial applications such as HEPA filter support, wastewater filtration, ventilation systems, and sludge treatment.

Advantages:

Excellent structural strength

High-pressure resistance

Long lifespan in harsh environments

Customizable aperture patterns

Withstands heat, chemicals, and weather exposure

Common Applications:

Industrial filter cartridges

Exhaust systems

Dredging and de-watering equipment

Wastewater sludge filtration

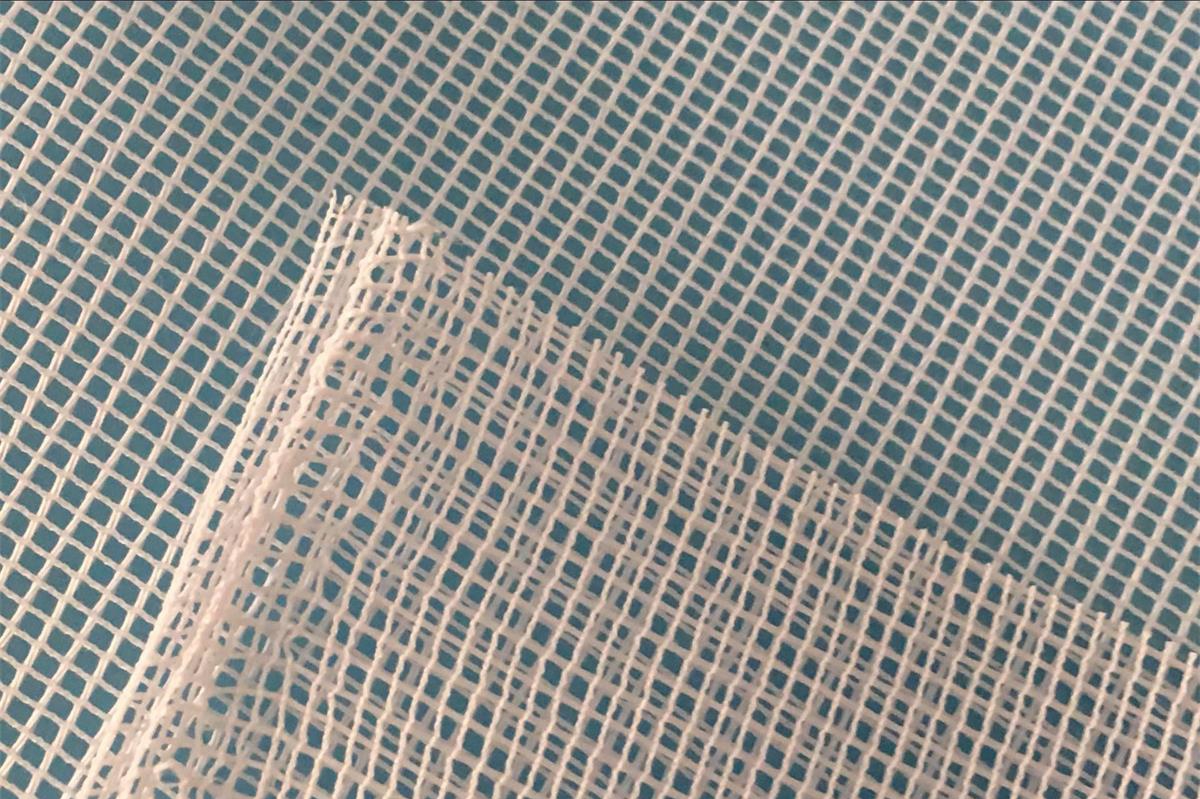

What Is Polyester Woven Mesh?

Polyester woven mesh is made from synthetic polymer threads woven together in a precise grid pattern. It’s lightweight, flexible, and widely used in low-pressure applications.

This mesh is commonly found in fine filtration systems for air, water, and even food processing. It’s affordable and easy to fabricate into different shapes and sizes, making it suitable for less demanding environments.

Advantages:

Lightweight and flexible

Easy to fabricate and install

Cost-effective for large surface areas

Non-corrosive in dry environments

Common Applications:

Air filters

Textile factory filters

Food and beverage processing

Laboratory filtration

Performance Comparison

1. Durability

Stainless steel perforated plate excels in extreme conditions. It can withstand high pressures, abrasive materials, and exposure to harsh chemicals. In contrast, polyester woven mesh is more vulnerable to mechanical damage and degrades faster when exposed to heat or chemicals.

2. Filtration Precision

Polyester mesh can achieve ultra-fine filtration thanks to its tight weave. However, stainless steel perforated plate offers better control over airflow and debris filtration in heavy-duty scenarios.

3. Maintenance

Stainless steel is easier to clean and resistant to biofouling. Polyester, although easier to replace, may need more frequent maintenance and replacement.

4. Cost

Polyester mesh is cheaper upfront. But if long-term durability and lower replacement frequency are important, stainless steel perforated plate is often more cost-effective over time.

Which One Should You Choose?

The right material depends on your specific requirements. If you’re working in a high-pressure, high-temperature, or corrosive environment, stainless steel perforated plate is your best bet. It’s designed for longevity and structural support. On the other hand, for lightweight or short-term applications with budget constraints, polyester woven mesh may suffice.

Think about the environment, lifespan, cleaning frequency, and budget. Then choose the material that best supports your long-term operational goals.

Industrial filtration is a critical component of modern operations—from protecting machinery to improving air and water quality. When selecting the right filter support material, weigh your options carefully.

Stainless steel perforated plate delivers unmatched durability, safety, and precision. It may be the higher investment upfront, but the long-term payoff is well worth it.

Would your system benefit more from flexibility or strength? The answer will lead you to the right material.

Request a Quote

Please email us via the contact form below, we will get back to you as soon as possible.