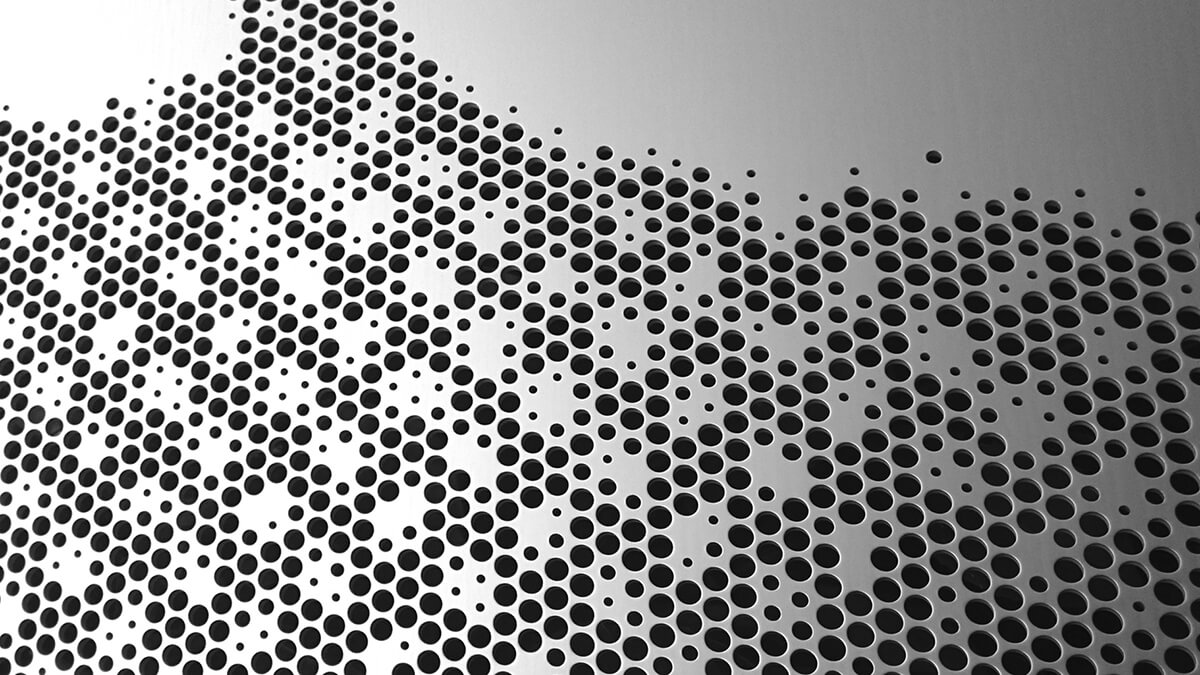

In modern engineering and industrial applications, perforated plates serve critical functions across architecture, automotive systems, and environmental protection, enabling structural support, ventilation, filtration, and aesthetic enhancement. Selecting the optimal aperture and material requires a careful evaluation of technical parameters and environmental demands to ensure optimal performance, durability, and cost efficiency.

1. Key Selection Parameters

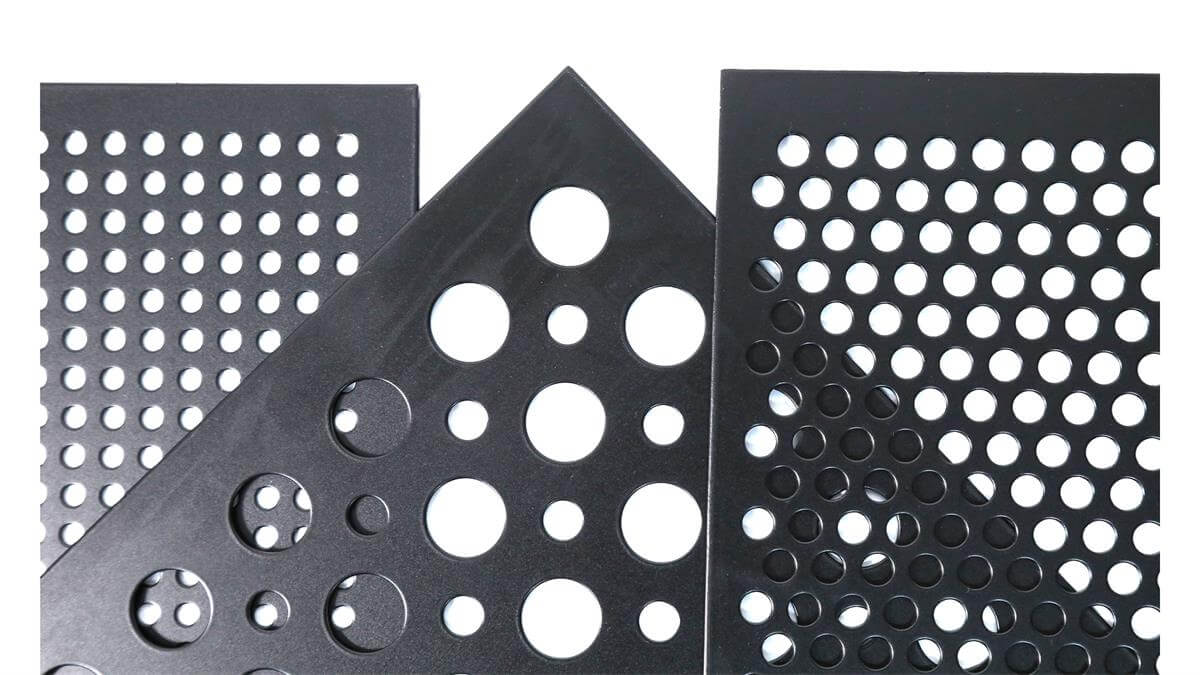

When specifying perforated plates, the following dimensions dictate functionality:

- Aperture Size (0.5–100 mm):

– Governs light transmission, airflow, and filtration precision.

– Smaller apertures (e.g., <1 mm) suit fine filtration; larger apertures (e.g., >10 mm) optimize structural ventilation.

- Hole Spacing (Pitch):

– Center-to-center distance impacts mechanical strength and deformation resistance.

– Tight spacing reduces open area but enhances load-bearing capacity.

- Opening Rate (10–70%):

– Calculated as:

– Higher rates improve airflow/acoustics but may compromise structural integrity.

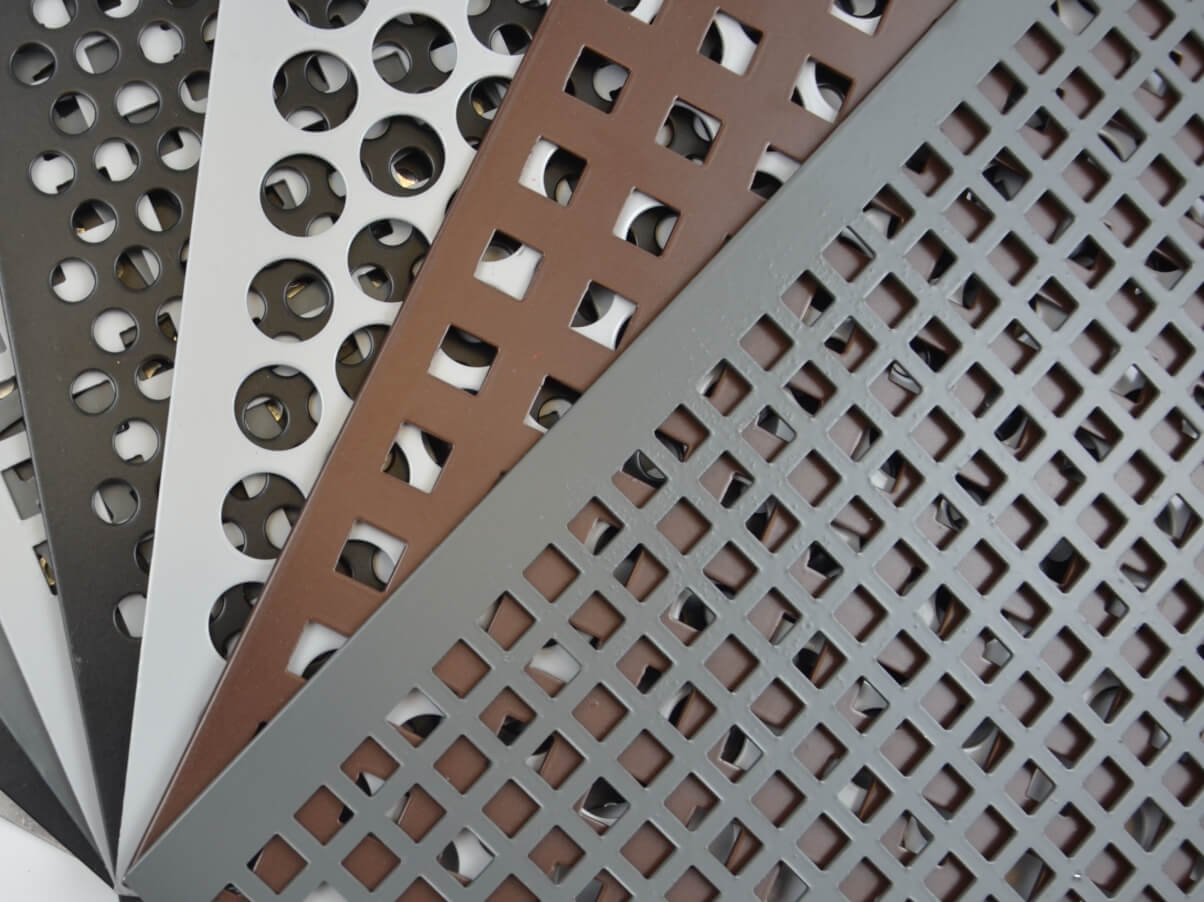

- Material Selection:

– Stainless Steel (304/316L): Corrosion-resistant for harsh environments.

– Carbon Steel: Cost-effective for structural applications (requires coating).

– Aluminum (5052): Lightweight (1/3 steel’s density) with natural oxidation resistance.

- Thickness (0.3–12 mm):

– Thinner plates (≤1 mm) are lightweight but prone to deformation; thicker plates (≥6 mm) withstand high-impact loads.

- Surface Treatments:

– Galvanizing, powder coating, or anodizing enhances corrosion resistance and aesthetics.

2. Industry-Specific Applications

1. Architectural Solutions

– Curtain Walls: 3–10 mm apertures, ≥40% open area for light diffusion.

– Acoustic Barriers: 1.5–3 mm apertures, 20–30% open area (noise reduction ≥25 dB).

Material Guidance:

– Coastal zones: 316L stainless steel (salt resistance).

– High-rises: ≥2 mm thickness with rib reinforcement (wind load ≥2.5 kPa).

2. Automotive Engineering

– Radiator Grilles: Diamond apertures (8×16 mm, ≥60% open area) reduce drag by 15%.

– Battery Enclosures: φ5 mm round holes with ribs (40% weight savings vs. solid plates).

Material Selection:

– Exhaust systems: 409 stainless steel (650°C tolerance).

– Light weighting: 5052 aluminum alloy.

– Safety: Apertures ≤8 mm to meet child safety standards.

3. Environmental Systems

– Wastewater Screens: Slotted holes (3×20 mm, >90% solids retention).

– Air Filters: 0.8–1.2 mm apertures (PM2.5 capture ≥95%).

Corrosive Environments:

– Titanium for chemical exposure.

– Duplex steel 2507 (PREN >40) for marine applications.

– Vibrating Screens: 6 mm thickness with stepped layouts (3× wear resistance).

3. Design Pitfalls & Optimization

– Aperture-to-Thickness Ratio: Maintain plate thickness ≥10% of aperture size to prevent buckling.

– Material Matching:

– Acidic gas (SO₂ ≤200 ppm): 316L stainless steel.

– Coastal areas (<500 m): 2205 duplex steel.

– High-temp (>800°C): 310S stainless steel.

– Cost-Saving Strategies:

– Architecture: Partial perforation (30% area) on carbon steel with spray coating.

– Automotive: Shared tooling for multi-model production (50% cost reduction).

– Filtration: Hybrid carbon/stainless steel designs for corrosive zones.

Conclusion

Selecting the ideal perforated plate hinges on balancing functional requirements (e.g., strength, filtration) with environmental constraints and budget. Architectural projects prioritize aesthetics and load capacity, automotive designs focus on weight and thermal management, while environmental applications demand chemical resistance and precision. By aligning aperture geometry, material properties, and industry-specific standards, engineers can optimize performance and lifecycle costs.

Why Partner With Us?

With 20 years of expertise and three manufacturing hubs, we deliver tailored perforated plate solutions—from rapid prototyping to high-volume production. Our in-stock inventory and custom capabilities ensure precision, speed, and reliability for your project’s unique demands.

Request a Quote

Please email us via the contact form below, we will get back to you as soon as possible.