In professional baking, consistency is everything. Whether you operate a commercial bakery, restaurant kitchen, or food production facility, the quality of your baked products depends not only on recipes and ingredients, but also on the equipment you use. Choosing the right oven is the foundation of success, and selecting the proper baking trays is the key to unlocking that oven’s full potential.

This guide will walk through how to choose a suitable professional baking oven, explain why stainless steel perforated baking trays make a critical difference, and introduce how HIGHTOP stainless steel perforated baking trays help professionals achieve reliable, high-quality baking results.

Part 1: Choosing the Most Suitable Professional Baking Oven

Before considering accessories or tools, the oven itself must meet professional standards. Unlike household ovens, commercial baking ovens are designed for continuous operation, high output, and precise control.

Capacity and Space Efficiency

In commercial environments, capacity directly affects productivity. A professional oven should offer sufficient internal space and a well-designed rack system to accommodate multiple trays simultaneously. Compatibility with industry-standard baking trays, such as 600 × 400 mm trays, is essential for efficient batch production and workflow optimization.

Precise and Uniform Temperature Control

Temperature stability is one of the most critical factors in baking quality. A professional oven should maintain minimal internal temperature variation—ideally within ±5°C. A strong forced-air convection system ensures that heat is evenly distributed across all tray positions, preventing common issues such as burnt edges, pale centers, or uneven rise.

Durability and Long-Term Performance

Commercial kitchens demand equipment that can withstand prolonged, high-intensity use. Ovens with full stainless steel interiors or heavy-duty enamel coatings are preferred, as they resist corrosion, are easy to clean, and maintain structural stability under high temperatures over long periods of time.

Steam and Functional Versatility

For products like European bread and artisan pastries, steam injection is essential to achieve proper crust formation. Additionally, ovens that support multiple functions—such as high-temperature baking, low-temperature drying, fermentation, and proofing—offer greater flexibility and allow businesses to expand their product range.

A professional oven is essentially a stable and precise production workshop. Once this foundation is solid, the next step is optimizing how heat interacts with the food itself.

Part 2: Why Stainless Steel Perforated Baking Trays Matter

Even the best oven cannot perform at its highest level if heat circulation is restricted. Traditional solid-bottom baking trays often trap moisture and block airflow, creating a steaming effect that leads to soggy bottoms, uneven browning, and inconsistent textures.

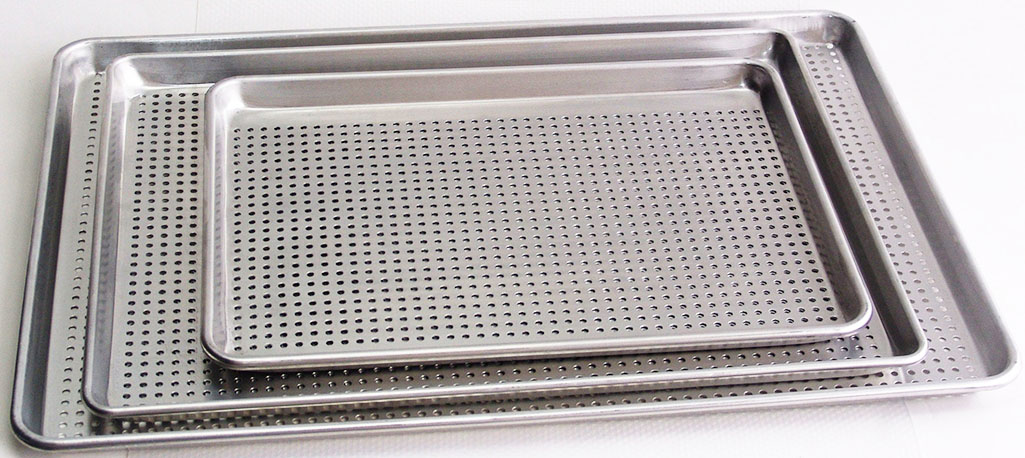

Stainless steel perforated baking trays are designed to solve this problem.

Enhanced Heat Circulation

Perforated trays feature evenly distributed holes that allow hot air to flow freely around and beneath the product. This creates three-dimensional heat circulation, ensuring that food is baked evenly from all sides rather than relying solely on bottom heat conduction.

Improved Product Quality

With better airflow, moisture and excess grease can escape during baking. The result is crispier bottoms, uniform browning, and improved texture—especially important for pizzas, European breads, cookies, pastries, and other products where surface quality and crunch are critical.

Higher Efficiency and Energy Savings

Improved heat transfer often leads to shorter baking times and more consistent results. This increases production efficiency and reduces waste caused by underbaked or overbaked products, helping businesses save both energy and raw material costs.

Durability and Hygiene

Stainless steel perforated trays are highly resistant to corrosion, deformation, and high temperatures. They are easy to clean, do not shed coatings, and maintain structural integrity even under frequent, intensive use.

Part 3: HIGHTOP Stainless Steel Perforated Baking Trays

HIGHTOP specializes in manufacturing high-quality stainless steel perforated baking trays designed specifically for professional baking environments. Each tray is produced using food-grade 304 stainless steel and precision perforation technology to ensure consistent hole size, flatness, and strength.

Key Advantages of HIGHTOP Baking Trays

-

Optimized Airflow Design: Evenly spaced perforations maximize hot air circulation for uniform baking.

-

Food-Grade Materials: Made from high-quality 304 stainless steel for safety, hygiene, and durability.

-

High Temperature Resistance: Maintains shape and performance under continuous commercial use.

-

Easy Maintenance: Smooth surfaces and corrosion resistance simplify cleaning and sanitation.

-

Customization Support: Available in standard sizes such as 600 × 400 mm, with full customization options to fit specific oven models or production needs.

HIGHTOP baking trays are widely used in commercial bakeries, central kitchens, food factories, and professional catering operations, where consistency, efficiency, and long service life are essential.

FAQ: How to Achieve Perfect Baking Results?

Q: What are the key factors for achieving perfect baking in a professional kitchen?

A: Perfect baking requires a combination of precise oven temperature control, uniform heat distribution, proper steam management, and the right baking trays. A professional oven provides the foundation, while stainless steel perforated baking trays ensure optimal airflow, moisture release, and even browning. When these elements work together, bakers can consistently produce high-quality products with the desired texture, color, and flavor.

By choosing a reliable professional oven and pairing it with HIGHTOP stainless steel perforated baking trays, baking professionals can significantly improve product quality, efficiency, and long-term operational performance.

Request a Quote

Please email us via the contact form below, we will get back to you as soon as possible.