Choosing the right hole pattern for architectural perforated metal is a multifaceted decision that bridges the gap between artistic vision and engineering precision. In modern architecture, these panels serve as the “skin” of a building, dictating everything from its thermal efficiency to its visual identity. To make an informed choice, architects and designers must evaluate several critical factors, ranging from the desired open-area percentage to the specific material properties.

1. Define the Primary Function of the Panel

Before selecting a pattern, it is essential to identify the primary performance requirements of the installation. Perforated metal is rarely just decorative; it usually performs a specific environmental or structural task:

- Solar Control & Shading: If the goal is to reduce solar heat gain while maintaining views, you should prioritize a controlled open area. A pattern with 20% to 30% open area can significantly lower cooling costs by diffusing direct sunlight.

- Airflow & Ventilation: For HVAC screens or parking garage facades, larger or more frequent openings (typically 40% to 60% open area) are necessary to ensure adequate natural ventilation.

- Acoustics: When used for interior ceilings or walls, perforated panels—often paired with acoustic backing—help absorb sound and reduce reverberation.

- Privacy Screening: Tighter patterns with smaller holes provide a “one-way” visual effect, allowing occupants to see out while obscuring the view for those outside.

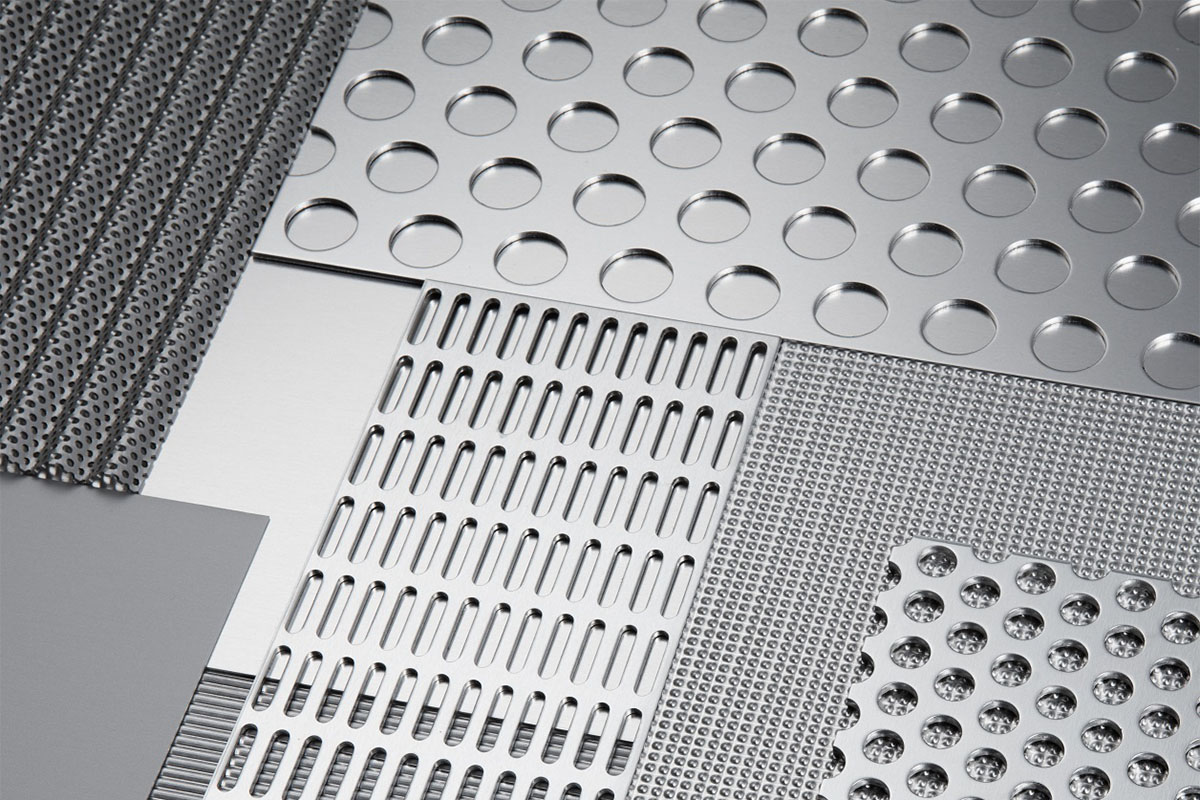

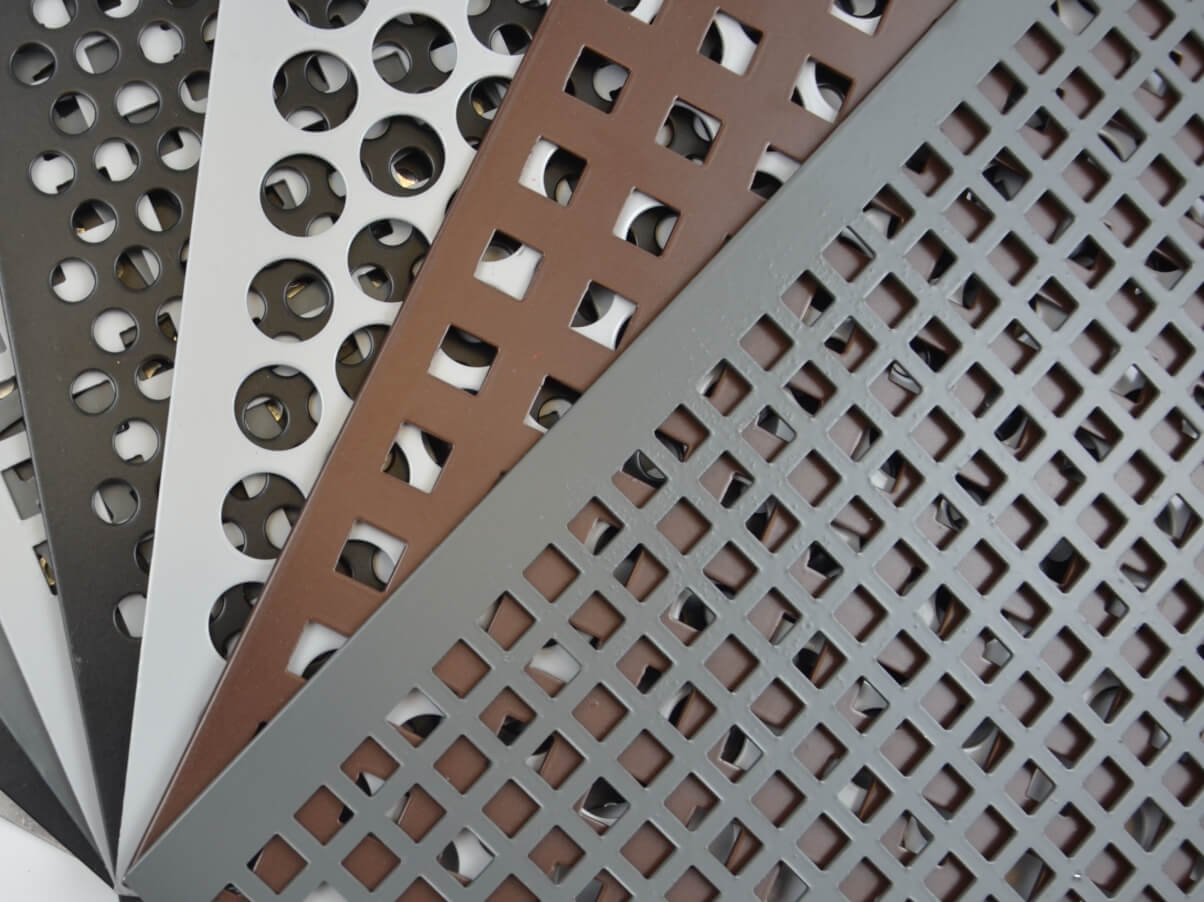

2. Select the Appropriate Hole Shape

The geometry of the perforation defines the “texture” of the building. While the choice is often aesthetic, each shape carries different structural and manufacturing implications.

Round Holes

Round perforations are the industry standard and the most cost-effective option. They offer the greatest structural integrity because they distribute stress uniformly across the panel. Round holes are highly versatile and are the most common choice for large-scale facades and sunshades.

Square and Rectangular Holes

Square patterns provide a clean, modern, and geometric aesthetic. They offer a higher open-area potential compared to round holes, making them excellent for applications requiring maximum transparency or airflow. However, they may require thicker materials to maintain structural stability due to the “bar” widths between holes.

Slotted or Oblong Holes

Slotted patterns are often used for directional control. They are particularly effective for privacy screens where light needs to be admitted from a specific angle while blocking views from another.

Decorative and Custom Patterns

With advanced CNC and laser-cutting technology, manufacturers like HIGHTOP can create custom “ImagePerf” designs. This involves varying hole sizes and placements to recreate logos, floral motifs, or even photographic images across a series of panels.

3. Determine Hole Size, Spacing, and Open Area

The relationship between hole diameter (D) and center-to-center spacing (C) determines the Open Area Percentage. This is perhaps the most critical technical specification.

- Staggered vs. Straight Patterns: A 60-degree staggered pattern is the most popular because it provides the highest strength and a pleasingly symmetrical appearance. Straight patterns are typically reserved for specific aesthetic “grid” looks.

- Technical Limit: As a rule of thumb, the hole diameter should not be smaller than the material thickness to avoid tool breakage and ensure clean edges.

4. Match the Pattern to the Material

The material choice impacts how the pattern will look and last over time.

- Aluminum: The preferred choice for architectural facades due to its lightweight nature and excellent corrosion resistance.

- Stainless Steel: Best for high-strength requirements or harsh environments (e.g., coastal areas).

- Galvanized Steel: A cost-effective solution for interior applications or industrial settings.

Why Choose HIGHTOP Perforated Metal Panels?

When selecting a hole pattern, the expertise of the manufacturer is just as important as the design itself. HIGHTOP Metal Mesh is a leading manufacturer with over 15 years of experience and three state-of-the-art factories.

The HIGHTOP Advantage:

- Precision Manufacturing: Equipped with over 100 sets of advanced equipment, including high-speed turret punches and laser-cutting machines, HIGHTOP ensures consistent quality and edge precision.

- Extensive Customization: Whether you need standard round holes or a complex custom pattern for a landmark project, HIGHTOP can accommodate diverse hole shapes ranging from 0.5mm to 50mm in diameter.

- Global Reliability: As an ISO 9001:2015 certified company, HIGHTOP exports to over 20 countries, offering a price advantage of 20%–30% compared to local distributors by shipping directly from the factory.

- Rapid Lead Times: Standard orders are typically processed within 7 days, helping architects keep their projects on schedule.

In conclusion, choosing the right hole pattern requires a balance of form and function. By considering the environmental needs of the building and partnering with a specialized manufacturer like HIGHTOP, you can turn a functional necessity into an architectural masterpiece.

Request a Quote

Please email us via the contact form below, we will get back to you as soon as possible.